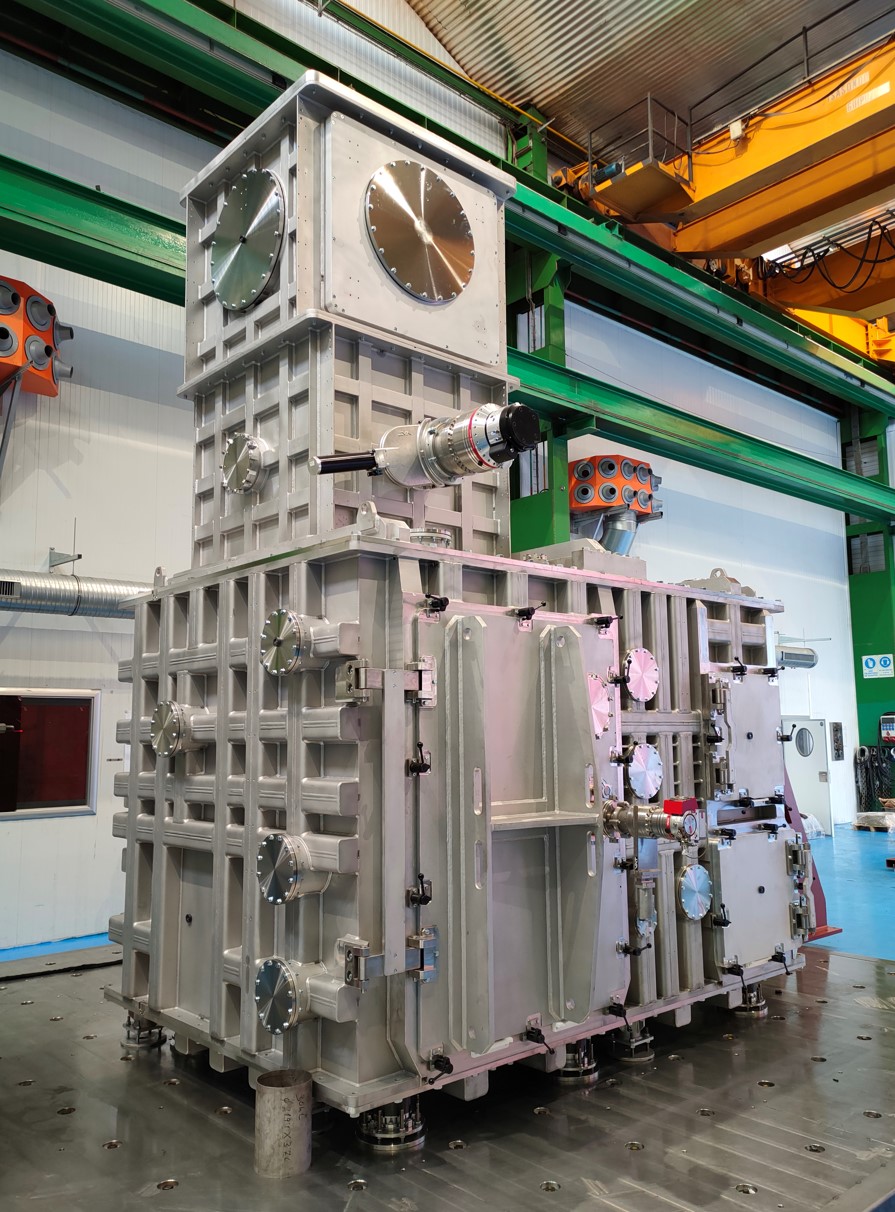

DETAIL DESIGN, MANUFACTURING AND TESTING OF VACUUM VESSEL FOR HIE-SOLDE CRYOGENIC

NOVEMBER 2013 - JANUARY 2015

CERN, SWITZERLAND / FRANCE

Alcance

DETAIL MANUFACTURING DESIGN

PURCHASING OF RAW MATERIAL

CUTTING, BENDING AND ROLLING

WELDING

NON DESTRUCTIVE TESTS

FINAL MACHINING

LASER DIMENSIONAL CONTROL

SURFACE TREATMENT (ELECTROPOLISHING, PICKLING and PASSIVATION)

ULTRASONIC BATH CLEANING

HELIUM LEAK TEST

FINAL SITE TRANSPORTATION

Especificaciones Técnicas

MATERIAL: 316LN (INOX AUSTENITIC STEEL)

VACUUM TIGHT WELD ACC. ISO 5817 QUALITY “B”

10% RADIOGRAPHIC TESTING ACC. EN 1435

LEAK TESTING ACC. EN 13185

– VACUUM: 10-7 mbar

– GOBLAL LEAK RATE < 1 x 10-10 mbar.l/s

CLEANING COMPATIBLE WITH ULTRA-HIGH VACUUM APPLICATION

HIGH TOLERANCES FOR FINAL MACHINING

– 0,05 mm IN POSITIONING and PLANITY